PRODUCTS

Specification

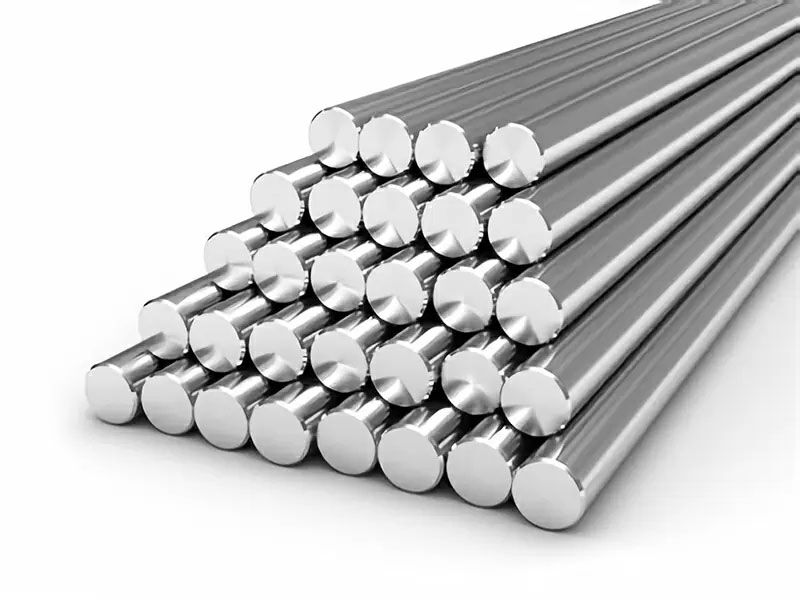

Overview of ASTM B164 UNS N04400 Round Bars:

Monel 400 alloy also known as nickel alloy 400, is an alloy made by adding copper, iron, manganese and other elements with metallic nickel as a matrix. Monel 400 alloy has good corrosion resistance and is silver-white, suitable for edge wire materials.

Uses of Monel 400 alloy:

The structure of Monel 400 alloy is a high-strength single-phase solid solution and single-phase austenite structure. It is a corrosion-resistant alloy with the largest consumption, the most versatile and excellent comprehensive properties. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated lye. At the same time, it is resistant to corrosion from neutral solutions, water, sea water, air, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance. The alloy is mainly used for valve stems, pump shafts and impellers, conveyor scrapers, oil well drilling rings, elastic parts, valve pads, etc.

Chemical Composition of Monel 400 Round Bar:

Carbon : ≤0.3, Silicon Si: ≤0.50, Manganese Mn: ≤2.0, Nickel Ni: ≥63, Copper Cu: 28~34, sulfur S: ≤ 0.024, Iron Fe ≤ 2.5

Physical Properties of Monel Alloy 400 Bar:

Density: 8.9g/cm3, melting point: 1300-1350 ℃, magnetism: none

Mechanical Properties of Monel Alloy 400 Round Bars:

Tensile strength: σb≥450Mpa, yield strength: σb≥170Mpa, elongation: δ≥30%

The hardness of hot-worked bars is 110~149HB for bars less than 54mm, 140~241HB for bars greater than 54MM, and 125~215HB for hot-rolled medium-thick plates.

The annealed state of thin plates is less than 73HRB, and the cold-rolled ones are greater than 93HRB. Of course, the hardness of the product is different. Fluctuation, tensile properties (RM/MPa): bar 590, cold rolled state 789, cold drawn state 775, annealed state 480, semi-hard state 520, fully hard state 808. Yield degree (MPAa): annealed state 398, semi-hard state 673, fully hard state 1111.

Application of Monel 400 UNS N04400 Round Bar:

Monel 400 is mainly used in the fields of chemistry, petrochemical, and marine development. It can be used to manufacture various heat exchange equipment, boiler feedwater heaters, petroleum and chemical pipelines, containers, towers, tanks, valves, pumps, reactors, shafts, etc.

About us

WHO WE ARE:

Bingcheng Stainless Steel is a proactive organization dedicated to providing high-quality products that meet and exceed customer specific requirements, thereby ensuring complete customer satisfaction. We are the professional manufacturer and supplier of metal material.

WHAT WE CAN SUPPLY?

As a manufacturer with 25 years experience in high-temperature alloy products, we have a professional service team to provide high standard of technical support, timely and qualified delivery, customs clearance assistance, and reliable after-sales services, etc.

Products Recommended

FAQ

Q: Are you trading company or Manufactuer?

A: Of course, we are manufactuer. We are in field of honed tube and chrome rod more than 20 years.

Q: What is your delivery time?

A: As normally, it is 25~60 days after you confirm the order. If your order is urgent, we would like to try our best to meet your requests.

Q:What is your main payment term?

A: They are T/T and L/C. Like 30% advance payment via T/T, balance pay after receive copy BL; 100% irrevocable L/C at sight. If you have any other requests, we can talk it again.

Q:What is your main market?

A:America, India, Korea, Pakistan, Turkey, Iran,Australian and so on.

Q: Why we choose you as our supplier?

A: All of our clients have reorders from us.Give us one order, you can feel our price, quality and service. Then, you will know us clearly.

Message