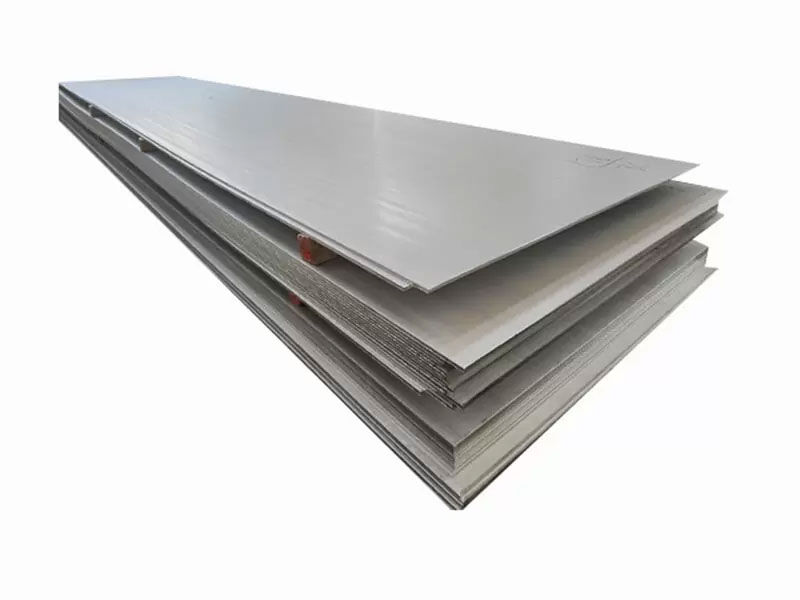

PRODUCTS

Specification

Inconel 601 alloy is a nickel-chromium-iron-based solid solution strengthened alloy. It has good high temperature corrosion and oxidation resistance, excellent cold and hot processing and welding properties, and has satisfactory thermal strength and high plasticity below 700°C. The alloy can be strengthened by cold working, and it can also be connected by resistance welding, melt welding or brazing. It is suitable for making anti-oxidation parts that can withstand low loads below 1100°C.

The performance characteristics of Inconel 601 are better than 600. It is an alloy with high chromium content. It has excellent oxidation and corrosion resistance. Because the composition also contains aluminum, it has good oxidation resistance and curing performance. The characteristics of this alloy are Excellent oxidation resistance and carbonization resistance at high temperature, good mechanical properties at room temperature and high temperature, good stress corrosion cracking resistance, high creep due to controlled carbon content and grain size Breaking strength.

Inconel 601 has different brand names in different countries, national standard brand numbers: NS3103, NS313, 0Cr23Ni63fe14al, American standard brand numbers: inconel601, No6601, German brand number: 2.4851, NICR23FE.

Inconel 601 chemical composition:

carbon C: ≤0.10, chromium Cr: 21~25, nickel Ni: 58~63, aluminum AL: 1.0~1.7, iron Fe: residual, manganese Mn: ≤1.00, silicon Si: ≤0.50, phosphorus P : ≤0.030, sulfur S: ≤0.015.

Inconel 601 physical properties:

density 8.11g/cm3, melting point 1308-1368°C, mechanical properties: alloy Inconel 600, tensile strength (MPA): RmN/mm2; annealing treatment at 650°C, solution treatment at 600°C, yield strength (MPA): RP0 .2N/mm2; annealing treatment 300-solution treatment 240, elongation: A5%, 30-30, Brinell hardness HB: annealing treatment.-solution treatment ≤220.

Inconel 601 processing and welding performance:

It has good thermal processing performance, the deformation temperature is 870~1230 degrees, the large deformation is 1040~1230, and the low plastic temperature is 650~871 degrees. Cold working in solid solution is a good effect. The strengthening effect is not as good as 18CR18NI. The heat treatment is between 1100 and 1150 degrees, which is easy to weld, but different parts use different processes and materials.

Inconel 601 corrosion resistance:

An important property of the alloy is its oxidation resistance at temperatures up to 1180°C. Even under severe conditions, such as heating and cooling cycles, a dense oxide film can be formed to obtain high resistance to peeling. Has good carbonization resistance. Due to the high content of chromium and aluminum, it has good oxidation resistance in high-temperature sulfur-containing atmospheres.

Inconel 601 application fields:

mainly used in heating equipment, chemical industry, environmental pollution control, and power industry. Such as heat treatment equipment and parts, various industrial furnace tubes, sleeves, flame nozzles, electric heating elements, resistance wire sleeves, condenser tubes for the chemical industry, equipment parts in HNO3 production, and heat-resistant and corrosion-resistant parts for the glass industry.

The chemical composition of Inconel 601 alloy

Physical properties of Inconel 601 alloy:

The minimum mechanical properties of Inconel 601 alloy at room temperature:

Characteristics of Inconel 601 alloy:

Excellent oxidation resistance at high temperature

Very good resistance to carbonization

Good oxidation resistance and sulfur-containing atmosphere

It has good mechanical properties at room temperature and high temperature

Good resistance to stress corrosion cracking. Because the carbon content and grain size are controlled, 601 has a higher creep rupture strength, so 601 is recommended in the field above 500 ℃.

Corrosion resistance of Inconel 601 alloy:

An important property of 601 alloy is its oxidation resistance at temperatures as high as 1180°C. Even under severe conditions, such as heating and cooling cycles, 601 can generate a dense oxide film to obtain high peel resistance. 601 has good resistance to carbonization. Due to the high content of chromium and aluminum, 601 has good oxidation resistance in high-temperature sulfur-containing atmospheres.

Alloy Inconel 601 application range Application area:

Pallets, baskets and jigs used in heat treatment plants.

Steel wire split annealing and radiant tube, high-speed gas burner , wire mesh belt in industrial furnace.

The isolation tank in the ammonia reforming and the catalytic support grid in the manufacture of nitric acid.

Exhaust system components

Combustion chamber of solid waste incinerator

Pipe support and soot handling department.

About us

WHO WE ARE:

Bingcheng Stainless Steel is a proactive organization dedicated to providing high-quality products that meet and exceed customer specific requirements, thereby ensuring complete customer satisfaction. We are the professional manufacturer and supplier of metal material.

WHAT WE CAN SUPPLY?

As a manufacturer with 25 years experience in high-temperature alloy products, we have a professional service team to provide high standard of technical support, timely and qualified delivery, customs clearance assistance, and reliable after-sales services, etc.

Products Recommended

FAQ

Q: Are you trading company or Manufactuer?

A: Of course, we are manufactuer. We are in field of honed tube and chrome rod more than 20 years.

Q: What is your delivery time?

A: As normally, it is 25~60 days after you confirm the order. If your order is urgent, we would like to try our best to meet your requests.

Q:What is your main payment term?

A: They are T/T and L/C. Like 30% advance payment via T/T, balance pay after receive copy BL; 100% irrevocable L/C at sight. If you have any other requests, we can talk it again.

Q:What is your main market?

A:America, India, Korea, Pakistan, Turkey, Iran,Australian and so on.

Q: Why we choose you as our supplier?

A: All of our clients have reorders from us.Give us one order, you can feel our price, quality and service. Then, you will know us clearly.

Message