PRODUCTS

Specification

INCOLOY 825

UNS Number N08825

Other common names: Alloy 825, Inconel 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper and titanium. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

In what forms is Incoloy 825?

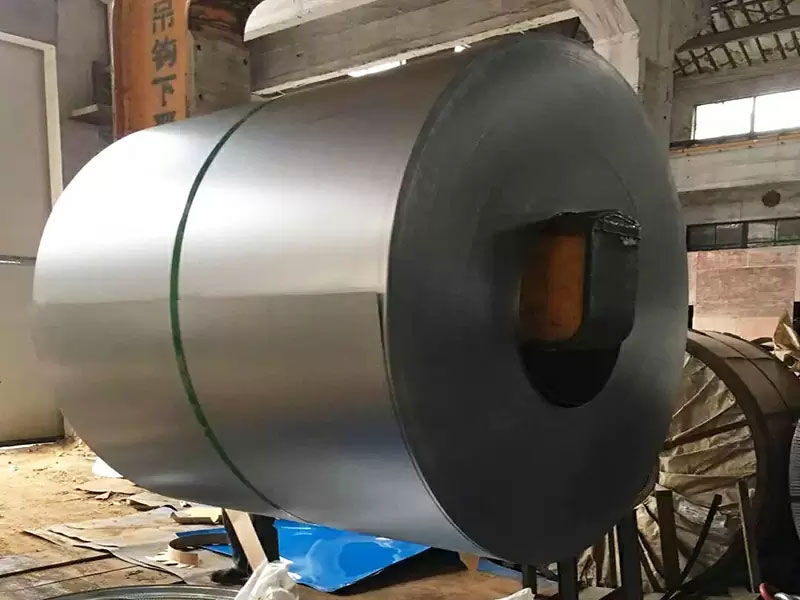

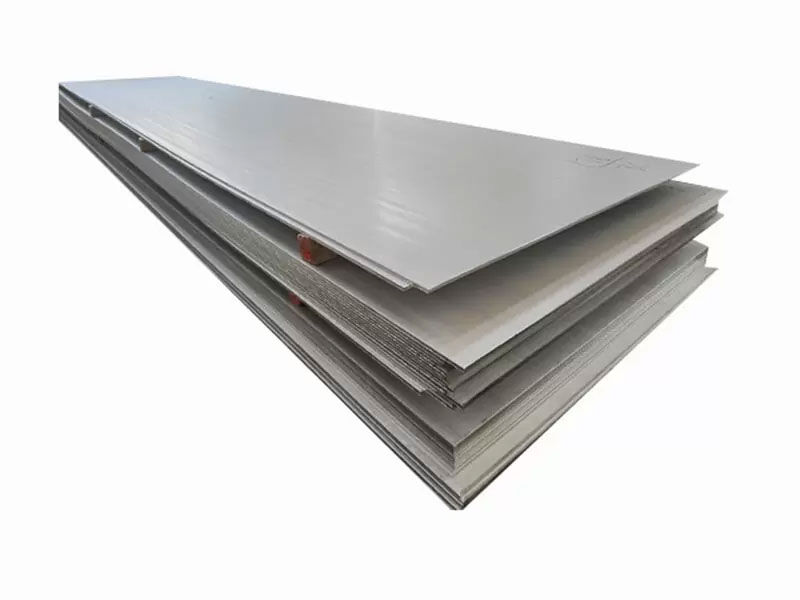

Sheet

Plate

Bar

Pipe & Tube (welded & seamless)

Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

What are the characteristics of Incoloy 825?

Excellent resistance to reducing and oxidizing acids

Good resistance to stress-corrosion cracking

Satisfactory resistance to localized attack like pitting and crevice corrosion

Very resistant to sulfuric and phosphoric acids

Good mechanical properties at both room and elevated temperatures up to approximately 1000°F

Permission for pressure-vessel use at wall temperatures up to 800°F

Alloy 825 (UNS N08825) Chemical Composition( %)

Corrosion Resistance

Alloy 825 has a high level of corrosion resistance. It resists general corrosion, pitting, crevice corrosion, intergranular corrosion, and stress-corrosion cracking in both reducing and oxidizing environments.

In what applications is Incoloy 825 used?

Chemical Processing

Pollution-control

Oil and gas well piping

Nuclear fuel reprocessing

Components in Pickling equipment like heating coils, tanks, baskets and chains

Acid production

ASTM Specifications

General Mechanical Properties

About us

WHO WE ARE:

Bingcheng Stainless Steel is a proactive organization dedicated to providing high-quality products that meet and exceed customer specific requirements, thereby ensuring complete customer satisfaction. We are the professional manufacturer and supplier of metal material.

WHAT WE CAN SUPPLY?

As a manufacturer with 25 years experience in high-temperature alloy products, we have a professional service team to provide high standard of technical support, timely and qualified delivery, customs clearance assistance, and reliable after-sales services, etc.

Products Recommended

FAQ

Q: Are you trading company or Manufactuer?

A: Of course, we are manufactuer. We are in field of honed tube and chrome rod more than 20 years.

Q: What is your delivery time?

A: As normally, it is 25~60 days after you confirm the order. If your order is urgent, we would like to try our best to meet your requests.

Q:What is your main payment term?

A: They are T/T and L/C. Like 30% advance payment via T/T, balance pay after receive copy BL; 100% irrevocable L/C at sight. If you have any other requests, we can talk it again.

Q:What is your main market?

A:America, India, Korea, Pakistan, Turkey, Iran,Australian and so on.

Q: Why we choose you as our supplier?

A: All of our clients have reorders from us.Give us one order, you can feel our price, quality and service. Then, you will know us clearly.

Message